2021 Update:

- As of January 2021, our 500g and 1kg bags is now fully domestically recyclable.

- Since Summer 2021, our 200g bags are now also fully domestically recyclable.

2022 Update:

- As of October 2022, we have replaced plastic bubble wrap that we used to protect our glass instant coffee jars with recycled shredded cardboard.

This is currently a test. If customers do not report breakages, we will continue with using this sustainable option. It has been a challenge as we need to protect the glass at the same time as considering a more environmentally friendly packaging option!

Why is coffee packaging so hard to recycle?

The combination of metal and plastic laminate makes it very hard to recycle and, much like supermarket wrapping etc, has to be put in the general refuse bin currently.

Unfortunately, this is the same for 99% of coffee brands right now - coffee bag packaging is not recyclable.

Why is this?

Coffee is a fresh product and can degrade and stale much like any food or drink product, think bread, fruit, etc.For Bird & Wild to be available on the retail shelf, we need to guarantee long shelf times, so that no coffee is wasted by the retailer. It's the reality.

In order to do that, we freshly roast our coffee beans straight into the bag and seal it, so that it's stored in a protected non-porous environment allowing for your fresh coffee to sold by retailers.This is where the metal-plastic laminate comes in. Oxygen is a killer of coffee freshness, so the environment needs to be completely non-porous.

There's also another factor at play: one-way valves.When coffee is roasted, it emits gases for up to 72 hours.If we packed the coffee in a bag and then sealed it up, it would explode because of the excess gas that builds up after roasting.So, a coffee one-way valve is required to allow this excess gas to escape, but to ensure that no oxygen to come back in.

As a result, you can enjoy the fresh taste of Bird & Wild Coffee for months after purchasing and it's a reality that, in order to supply customers, we need to have a reasonably long shelf life.The combination of a one-way valve and the metal-plastic laminate make it very hard to recycle currently.

The Good News?

Our expertise is coffee sourcing and roasting - not packaging, which is manufactured by packaging companies, but the good news is that the packaging industry is at last coming up with solutions.

We have been meeting and testing various options and the good news is that:

- As of January 2021, our 500g and 1kg bags is now fully domestically recyclable.

- As of the Summer 2021, our 200g bags are now also fully domestically recyclable.

On your right is the new 1kg and 500g bags look like as of January 2021:

What type of recyclable packaging are you using?

LDPE (PE4) can be recycled. However, you will need to check with your Local Authority to ensure it is recycled in your area. This is a hard flexible plastic.

You can recycle this plastic if your Local Authority mentions:

- Bread bags

- Frozen food bags

- Squeezable bottles i.e hand cream tubes

- Bubble wrap – if specifically mentioned

- Carrier bags that can be stretched – Local authorities often don’t collect carrier bags, but can be recycled in local supermarkets

LDPE can be recycled into bin liners.

The laminate is made up of recyclable laminate that can be recycled at home, but is the duty of local councils to correctly recycle the materials.

Usually, councils would provide the wheelie bins for household to separate waste, but some councils may omit certain types of plastic from their “recyclable bins”.

Ultimately, the recyclability of materials depends on the technologies available to councils to process household waste.

Why not use compostable/biodegradable packaging?

We get this question a lot...On paper, plastic-free compostable and biodegradable packaging sounds like the right way to go?

Unfortunately not...

- Compostable and biodegradable technology has come on leaps and bounds, but it is still often not oxygen-proof/too porous to keep coffee fresh.

- To have fresh coffee, you need one-way valves, and getting a compostable valve is very difficult to achieve indeed.

- But, the biggest reason is that waste refuse companies find compostable and biodegradable packaging very hard to process.

You can't just put them in the ground and let them biodegrade.

You need to use industrial composting methods on a large industrial scale. As a result, more often than not, that "biodegradable" packaging you put in the brown bin will be removed by the refuse company and dumped in landfill. That's the reality.

So, for the time being, like most of the coffee industry, we're moving to recyclable material instead...

Environmental Programs at the Roastery

Roaster Catalytic Converter - converts CO into CO2

Chaff Compactor - reduces the waste disposal of the Chaff and therefore the carbon footprint of Trucks / Skips

Heat Generation from the Roasters - is used to warm the factory reducing the energy usage

Hessian & Jute Coffee Bags - are sold to Farming industry, Retail industry and into Recycling

Lighting - the whole facility is converted into using energy efficient LEDs

Environmental Programs at the Warehouse

RECYCLING

Our waste is minimal with all excess cardboard and paper products delivered to our warehouse either re-used as packaging or baled and recycled into more fresh cardboard and paper, the boxes we receive we re-use as packing boxes or for our own use within the warehouse and excess cardboard is shredded to be used as packing material in our warehouse.

PLASTIC AND WASTE

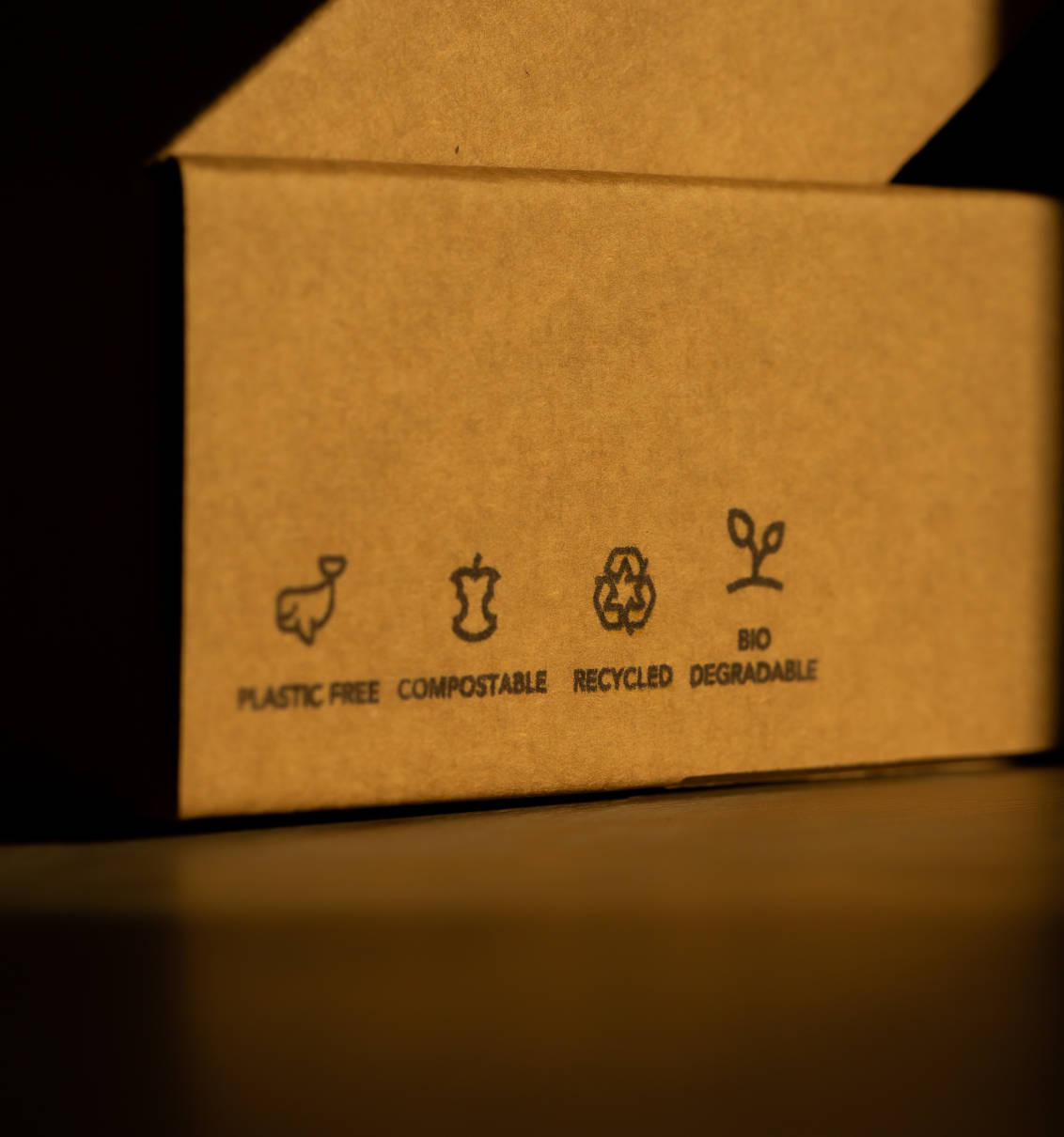

All mailing bags and boxes are fully biodegradable.